Mist Containment Station

Promotes a Cleaner Shop Environment

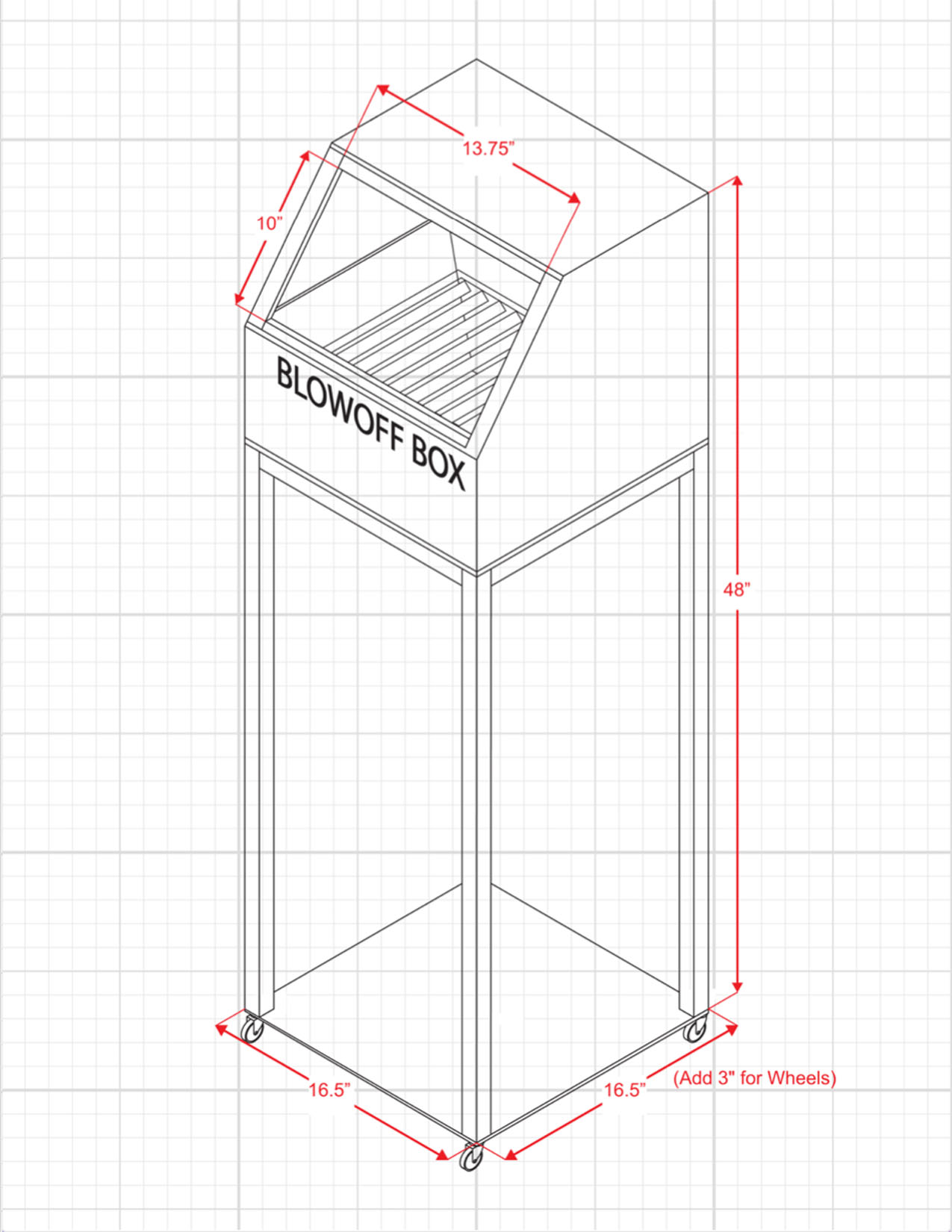

The operator holds the part in the slanted opening of the box, 10”H x 13.75”W. The parts are then sprayed / “cleaned off” with compressed air using the attached air gun. Simultaneously, the operator presses down on the foot pedal located at the base of the unit. As compressed air passes over the orifice of the venturi vent, located at the bottom of the cabinet, smoke and debris from inside the cabinet are sucked down away from the operator and into the plastic bucket. There are no fans or moving parts. Clean air passes back up and through the air filters, while the fluid is held in the bucket. Top, bottom & side flanges prevent the escape of fluid coating and/or debris as they are sprayed off the parts. Metal mesh filter is opposite the opening inside the box to absorb spray deflection. A grate fits over the funnel to prevent parts from dropping down into the bottom of the box.

Features & Benefits

Downdraft Effect Contains Contaminants

Handheld Air Nozzle Ensures Debris

Easy Cleaning Housing & Debris Bin

16 Gauge Steel Sheet & Tube Frame Construction

1/4” NPT Filter – Regulator & Isolation Valves

Manufactured in the USA

3 Year Warranty

Dimensions

Opening: 10" H x 13.75" W

Overall: 6.5" W x 16.5" L x 48" H

| Image | Title | Price | Details |

|---|

3 Stage Filtration

Our mist containment station uses 3 stage filtration technology to create the most vaccuum to eliminate as must mist and debris from the part and air as possible.

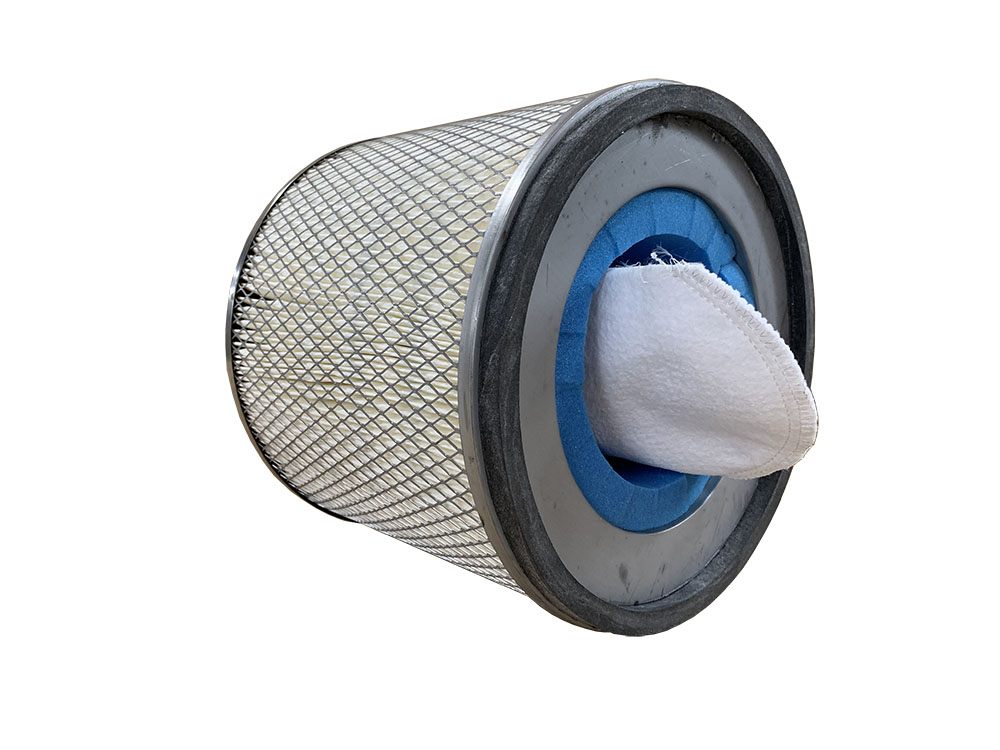

Stage 2: Affixed to the inside of the circular air filter is a blue filter that will filter out thinner viscosity oils that are being cleaned off the recently machined parts, as well as collect some smaller metal debris.

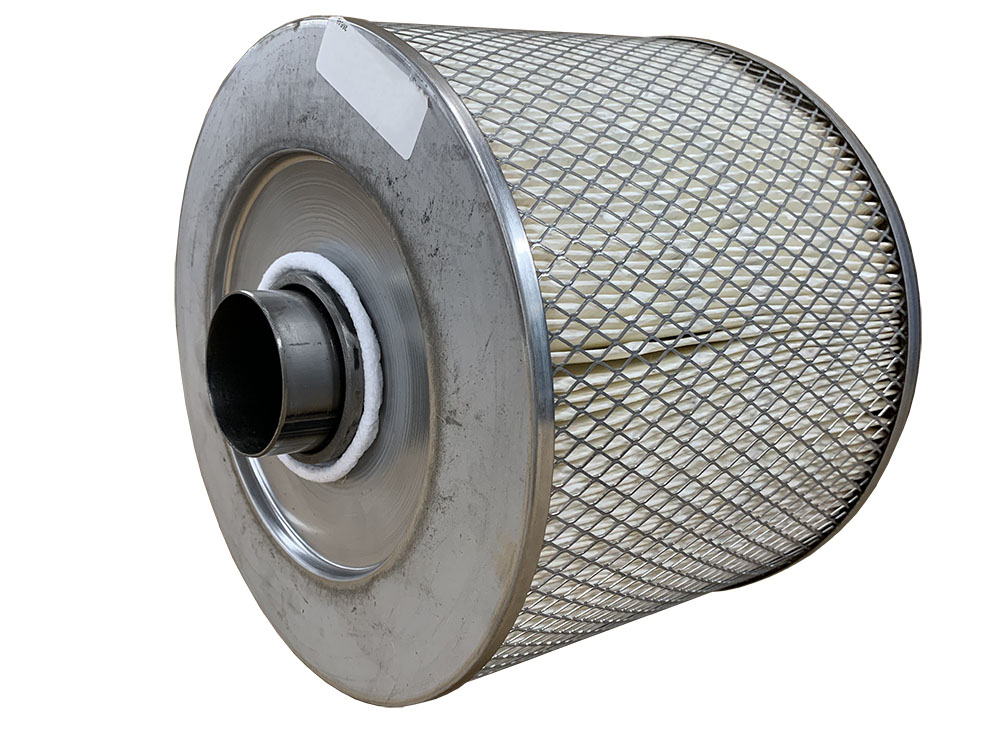

Stage 3: Affixed on top of the bucket and situated below the box is a 12.11” OD circular air filter with paper and fabric fins on the sides. This air filter has a metal top with a 3.03” round opening. This opening is for the exhaust tube. The positive air pressure, having passed down the exhaust tube and through the stage 1 wet sock filter, passes upward from the bottom of the bucket and through the stage 2 filter, and then through the stage 3 filter before being released into the ambient factory air.