Turbocharge Your Mist Collector

Electrostatic air filtration units (Tri-Mist – MistBuster – CoolBlaster – Smog Hog – Trion units) are the most efficient way to remove oil laden mist from CNC units because they do not clog up like traditional media filters. However in many factories I see the large media post HEPA filters mounted on top of MistBuster and Tri-Mist electrostatic air filtration units. In probably 90% of these applications the HEPA filter is actually causing more of a problem then a solution. The main reason is that not all the mist is removed prior to the HEPA filter. HEPA filters then pick up the bulk of the air filtration work and clog up quickly as a result of their high efficiency. The oily mist generated in the CNC machining cabinet then escapes out the chip conveyor or from the bottom of the CNC unit because of the reduced suction. The key is to remove as much oil particulate as possible pre electrostatic filtration; not post electrostatic filtration.

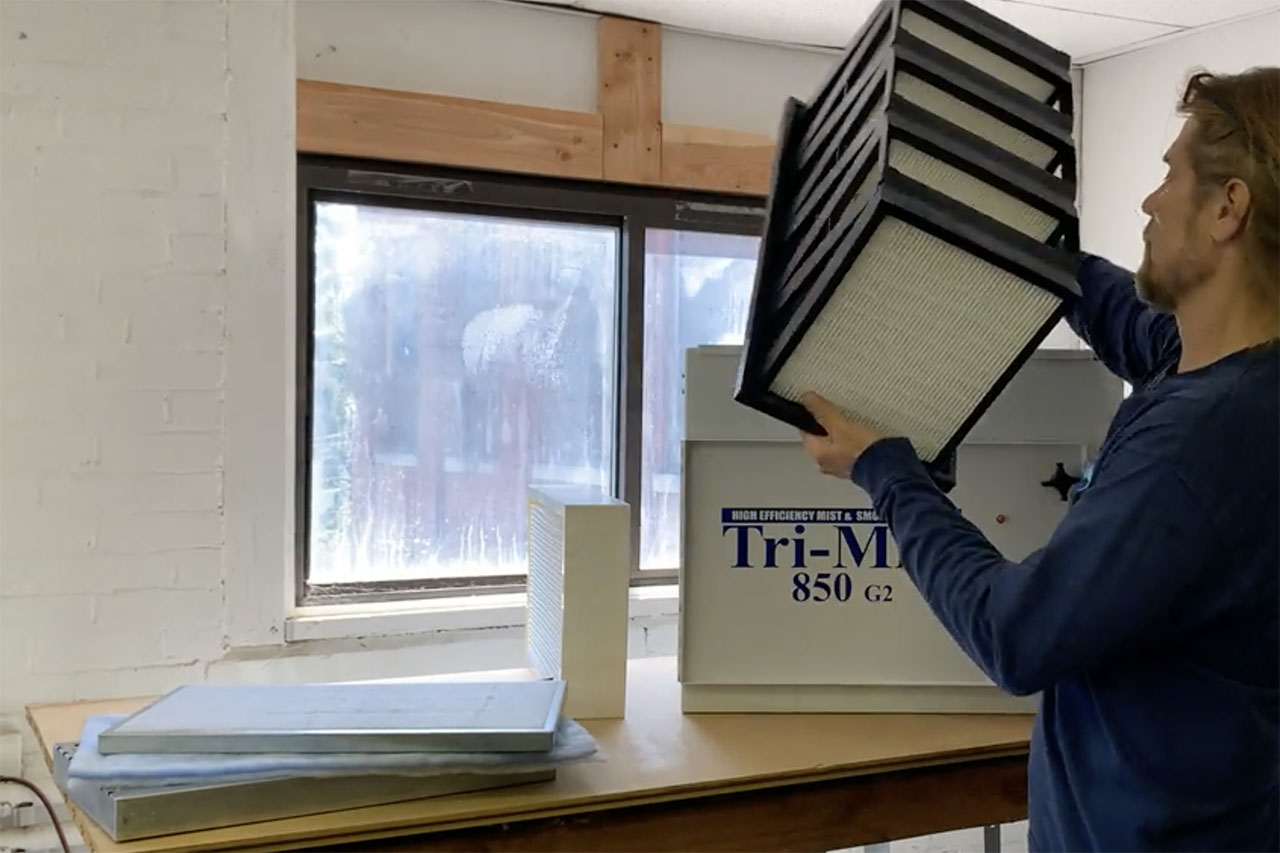

Configure the filters in the following way for the highest efficiency starting with the bottom filter first

Stage #1: 1″ metal mesh filter (Primary purpose is to knock out metal chips from being sucked into the unit)

Stage #2: Dacron Filter (Primary purpose, to knock out some heavy oil mist / smaller metal chips)

Stage #3: 2″ metal baffle (Primary purpose, to knock out some oil mist)

Stage #4: Electrostatic Cell: (Main filtration of oil particulate down to .03 microns in size)

(Depending on the type of unit, anywhere from 1-6 electrostatic cells)

Stage #5: 1″ Post dura mesh filter: (To create back-pressure to moderate airflow over the electrostatic cells)

Stage #6: Aeolus 95% Post Filter: (Polish the air)

(Optional – in lieu of HEPA filter; deigned for wet particulate – less clogging)

With this configuration, AND ROUTINE MAINTENANCE, you will optimize the best performance from the MistBuster / Tri-Mist units AND HAVE MUCH CLEANER AIR.

| Image | Title | Price | Details |

|---|