The Key is Routine Maintenance

MistBuster & CoolBlaster series units are source capture air filtration units that remove oil mist and smoke from CNC cabinets. These units come in different sizes (500, 850,Quad, 2000) and have odor control post filters which can be added on.

Electrostatic units can remove particulate in the air as small as .03 microns and run with relatively small motors vs. a traditional media filtration unit, resulting in significant energy savings.

Maintenance on these units however can be challenging as there are more components of the machine to check vs. a media type unit. The first rule of thumb with these units is to clean the collection cells at a pre-determined frequency; usually 4 times per year, otherwise oil and other debris can coagulate between the collection cell plates and cause the cell to “arc out” or ground, nullifying air filtration. The less you clean them the harder they are to clean. The second rule of thumb is to watch the indicator light, usually orange or red and located to the right of the door. If the light is blinking or not on, it indicates that the collection cells are not working and that the unit needs to be serviced and or repaired. If you are attempting to clean a large number of collection cells, then parts washing equipment and replacement collection cells are recommended in order to avoid significant machine down time.

- Be careful when working with the electronic cell.

- The edges of the collector plates and the ionizing wires on the cell may be sharp.

- When cleaning the cell, be sure to wear appropriate protective gear, especially goggles and gloves.

- Skin contact with alkaline detergent solution should be avoided.

- The electronic cell must be handled with care to avoid damage.

Procedure for MistBuster and CoolBlaster Air Filtration Units

Step 1: Turn the machine off and or unplug the unit from the power source. Wait 10 seconds then proceed to step 2. The collection cells carry a charge which can cause a shock if the cell is touched prior to it being grounded.

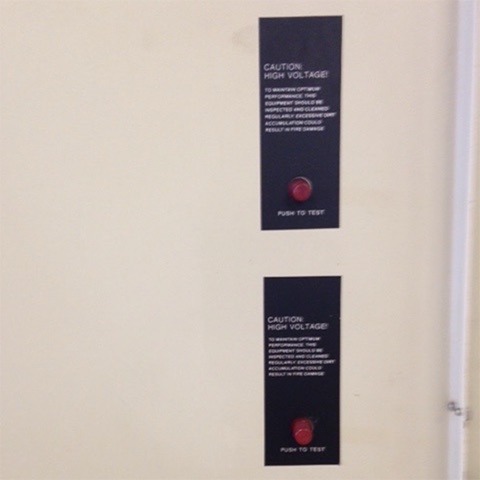

Step 2: Press down the ground button located on the door of the unit, depending on the size of the unit there can be more than one ground button. (See photo)

Step 3: Open the door and ground out collection cell(s)

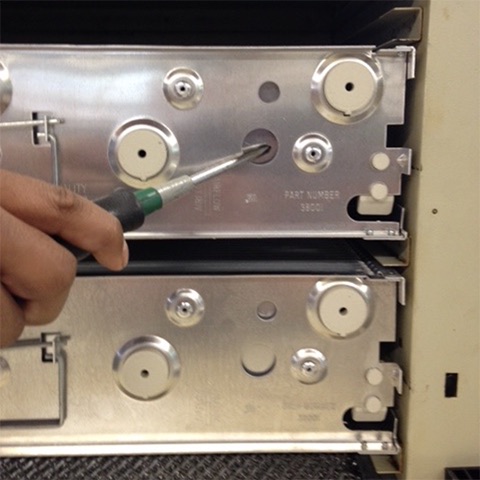

Using an insulated screw driver, place the tip of the screw driver on the collection plate, while simultaneously resting the metal edge of the shaft of the screw driver against the frame of the cell. (See photo) You may see an arc depending on whether the cell was charged.

Step 4: Remove the collection cell(s) and pre and post mesh filters. The mesh filters are used to prevent any large debris from getting lodged in between the collection cell plates. The collection cells and mesh filters are now ready to be cleaned.

Step 5: Cell Cleaning:

- Method #1 Soaking: Completely submerge and soak the collection cells with the appropriate electrostatic cell cleaning detergent for 1 hour. The use of the proper detergent is extremely important as the wrong type of detergent can damage the aluminum fins. Use a plastic wash container (24” x 24” x 20) in size. After the cells have soaked, rinse with steady strong water pressure ensuring that any residue is removed from the collection plates. Water Pressure should not exceed 60 psi as the collection plates can be bent and touch one another, rendering the cell inoperable. To ensure proper cleaning, drain and refill the wash container after every two filters cleanings. Ensure that the emptied cleaning fluid is disposed of in accordance with local EPA regulations.

- Method #2 Parts Washer: The mist impingers and electronic cell can be cleaned with a parts washer. Make sure that the cleaning fluid used is aluminum sage and the maximum pressure does not exceed 60 psi.

Step 6: Inspect the cleaned collection cell, there should be (9) ionizer wires located on one side. (see photo) If any of these wires are missing they must be replaced, otherwise the collection cell will not function to its full capacity. In addition, inspect the collection cell plates, ensure that each plate is not bent or touching another, otherwise the cell will not work. If you see any debris lodged between the collection plates, they can be blown out with air. (Be careful not to bend the collection plates with too much pressure)

Step 7: Cleaning the interior cabinet. Use Simple Green or a similar type cleaner / degreaser and thoroughly clean the cabinet contact points from any excess grease. (Contact point(s) colored red in photo) If there is a buildup of burnt oil / grease on these points they may not charge the collection cell once re-inserted in the cabinet. If the contact points appear charred then it will need to be replaced, access to the contact point is gained by removing the side panel of the unit exposing the power packs and internal wiring.

Step 8: If there is an inlet plenum attached to the Mistbuster / Coolblaster, check drain & inlet flex hose to ensure that neither is clogged.

Step 9:

- Re-insert the cleaned collection cells and mesh filters in the same order that they were removed. There is a little arrow stamped on the cells, make sure the arrow is pointing up. The ionizer wires should be facing down as the cell is inserted. Pay attention, if cells are inserted upside down, unit will not work.

- Units with a 2” stage one Impinger should install this next, mesh filter situated on top.

- Some units have two 2” mesh filters rather than the Impinger section(s). Reinsert the mesh filters with the arrows point up.

Step 10: Close the door and hand tightened down the knobs ensuring that the seal is thoroughly pinched between the door and the unit. Turn the machine on, a solid indicator light means everything is working properly.

How Can We Help?

In theory it always sounds good to clean electrostatic precipitators yourself but it can be very time consuming or more expensive if you break important hard to get parts. Smaller jobs may be more doable but even then you have to deal with chemicals and cleaners that are not environmentally friendly. Rather than try to figure all that out it may be better to out source the work to a professional company that is better suited for the job and more cost effective in the long run.