Tri-Mist Air Cleaning Solutions

The TriMist air filtration system (often used in industrial or manufacturing settings) is designed to remove oil mist, smoke, and particulate contaminants from the air—particularly in environments with CNC machines, grinding, or metalworking operations. Here are the main benefits of using a TriMist system:

Cleaner Air = Healthier Workplace

- Captures oil mist, smoke, and fine particulates before they can be inhaled.

- Reduces respiratory issues and long-term exposure risks for employees.

Improved Indoor Air Quality

- Keeps air free of fine mist and airborne contaminants.

- Helps maintain a more pleasant working environment, free of chemical or burnt oil odors.

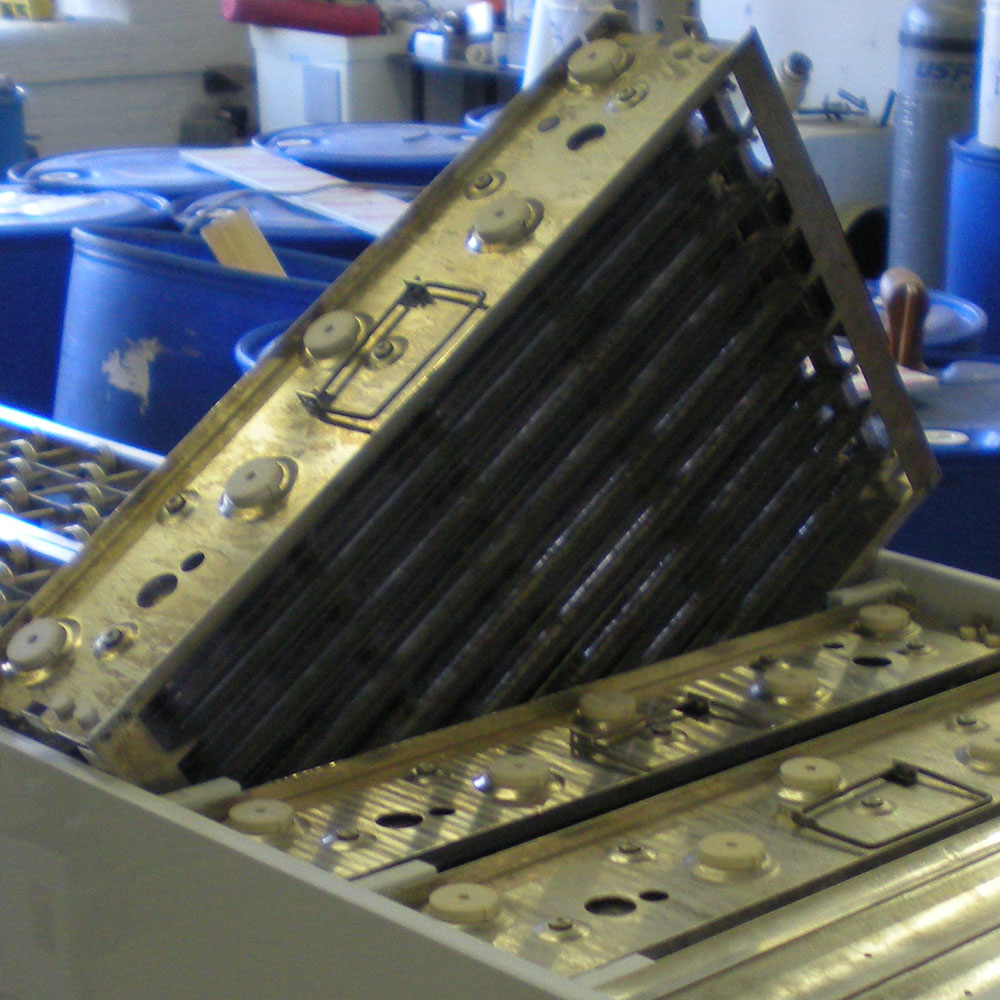

Efficient & Multi-Stage Filtration

- Many TriMist units use multi-stage filters (like pre-filters, HEPA, and carbon).

- High-efficiency filters trap up to 99.97% of particles, including sub-micron-sized pollutants.

Compliance with Safety Standards

- Helps businesses meet OSHA and EPA air quality regulations.

- Reduces risk of fines or shutdowns due to poor air quality management.

Equipment Protection & Reduced Maintenance

- Cleaner air = Less buildup of mist and particulates on sensitive machines.

- Extends the lifespan of electronics, control panels, and machinery.

Cost Savings Over Time

- Less frequent need for cleaning, maintenance, and repairs.

- Fewer health-related absences or incidents.

TriMist Air Filtration Products and Applications

- 500, 750, 850, 1000, 1400, Quad

- CNC

- Machining

- Press Machinery

- Manufacturing

- Restaurants

- Automotive

- TriMist Replacement Parts

- TriMist Cleaning Service

- TriMist Filter Replacement Kits

Common Replacement Parts

- Filters

- Capacitors

- Ionizer Wires

- Latches

- Lights

- Springs

- Power Supplies

- Cells